For the production of plastic parts we use Arburg injection moulding machines with clamping forces from 50 to 220 tonnes including standard peripherals. We can provide threaded inserts, painting and printing of parts. We produce parts up to 850g.

Serial and prototype production of plastic parts is realised by 3D printing. We currently use FFF technology up to a size of 600x400x800 and MSLA technology up to a size of 300x200x400.

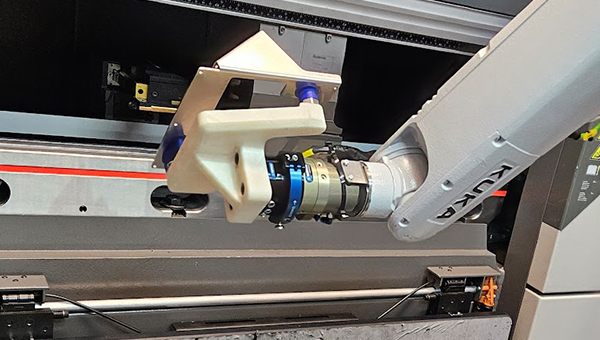

For the production of chassis, electronic brackets and support elements for equipment, we process thin sheets up to 3 mm thick. For precision bending, we use the Bystronic Mobile Bending Cell 40 robotic workstation. Finished parts can be fitted with press and rivet elements, wet or powder coated and printed.

We produce glass control panels. Depending on the requirements, graphics are prepared and printing parameters are set to create transparent and translucent parts of the graphics. The panels are also fitted with a capacitive touch sensor, usually connected to the instrument itself via an I2C bus.

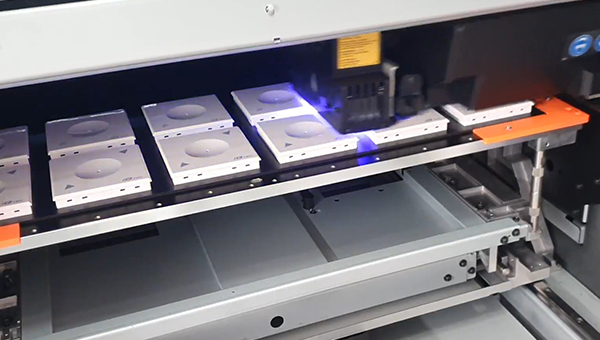

We print plastic and metal parts. We use a Mimaki digital UV-LED printer with a working area of 610x420 mm. The advantage of printing is high colour stability, abrasion resistance and chemical resistance. We print flat objects up to a height of 150 mm, including glass.