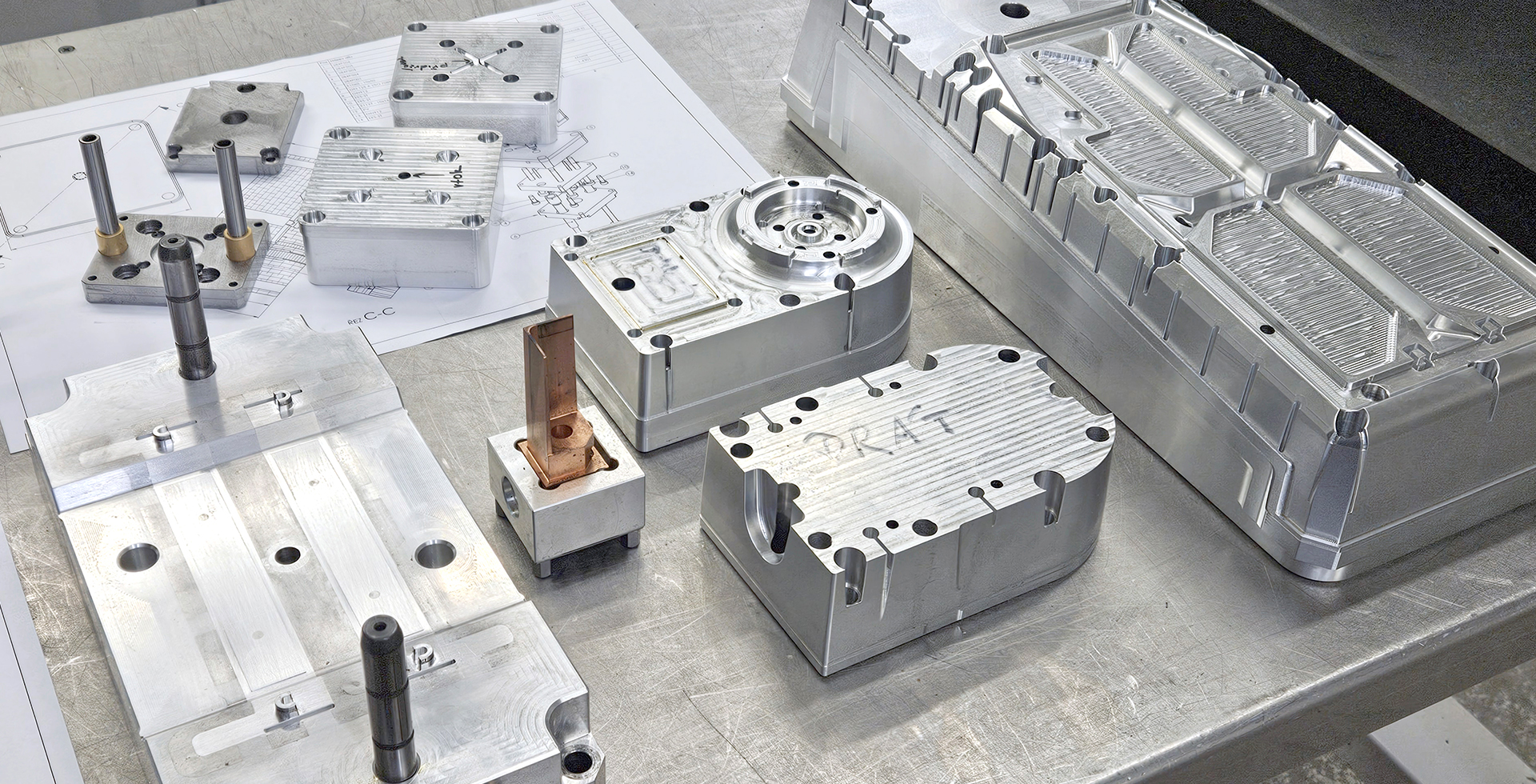

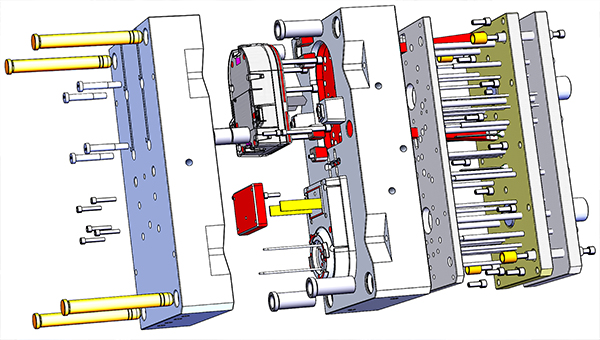

Our engineers prepare concepts and produce detailed technical documentation for the moulds. During the preparation process, we perform simulations that allow us to optimise melt flow and minimise deformation of future parts.

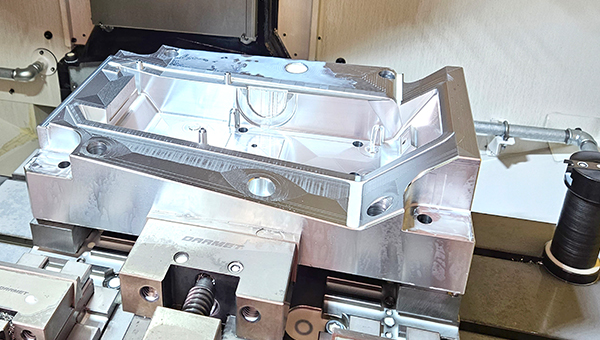

Milling plays a key role in the production of parts for the future tool. We use the HSM Works CAM system in conjunction with a FANUC Robodrill D21LiB5 24k high speed CNC machining centre to achieve precision machining of individual parts.

For details that cannot be machined in the traditional way, we use EDM machining. We use a modern Sodic AD35L CNC sinker for surface, hole and support production. For precision cutting we use a Sodic VN400Q CNC wire EDM.

We pay the utmost attention to the finishing of the mould surfaces, using a combination of blasting and laser engraving to create the finish. Surfaces with high gloss requirements are finished by hand.

The individual parts of the moulds are precisely assembled into the final product at manual workstations. In order to achieve the best possible moulding of the parts, we finish the moulded surfaces on a PROTH PSGS 3060 NC grinding machine, and the ejectors and pins are precisely cut on a Meusburger GMT 6000 cutting machine.

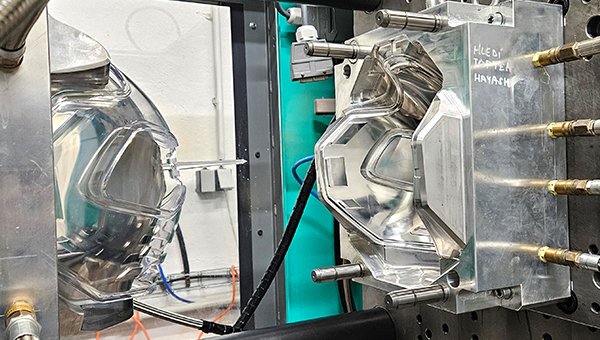

Every mould produced is thoroughly tested in our own moulding shop. This ensures that it meets the quality requirements and that it will operate correctly in an automated environment. Once the samples have been approved, we are ready to produce the parts in series. We use modern Arburg presses with clamping forces from 50 to 220 tonnes.